Sofca srl is able to integrate various screwing and tightening tools, used by a plurality of operators, and perform the data transfer to a filing system based on the use of:

- PLC

- PC

- Sniffer

- PFCS

- Company Server

via multiple alternative interfaces, such as:

- Discrete signals

- RS232 / 422 Serial

- Ethernet

- Profinet

interacting on an information technology level and in real time with the control systems that contribute to the complex vertical supervision activity according to various types of networks and protocols including PFCS / MES.

Therefore, systems of various complexity can be configured with centralized data management on the server of the customer's plant, passing from the creation of minimal systems consisting of a tool with control unit, beacon, printer, optional barcode reader to hybrid systems with more than one tool connected to a control unit up to systems integrated with company data management, where the fulcrum of the system is a Sofca standard industrial touch-screen PC.

Three typical configurations can be identified:

- Integrated systems with independent operating mode

- Integrated systems with deferred operating modes

- Integrated systems with simultaneous operation mode

But it is also possible to compose integrated systems with mixed operating modes; they are hybrid systems composed of subsystems of the previous types.

Example:

Integrated systems with independent operating mode

In this case, each system operates independently; one operator per system is employed.

Integrated systems with deferred operating modes

In this case, each system operates virtually independently, but the access by the control unit is divided over time and the control unit is dedicated to one tool at a time after each access; only one operator is used for all the tools in the group.

Example:

Example:

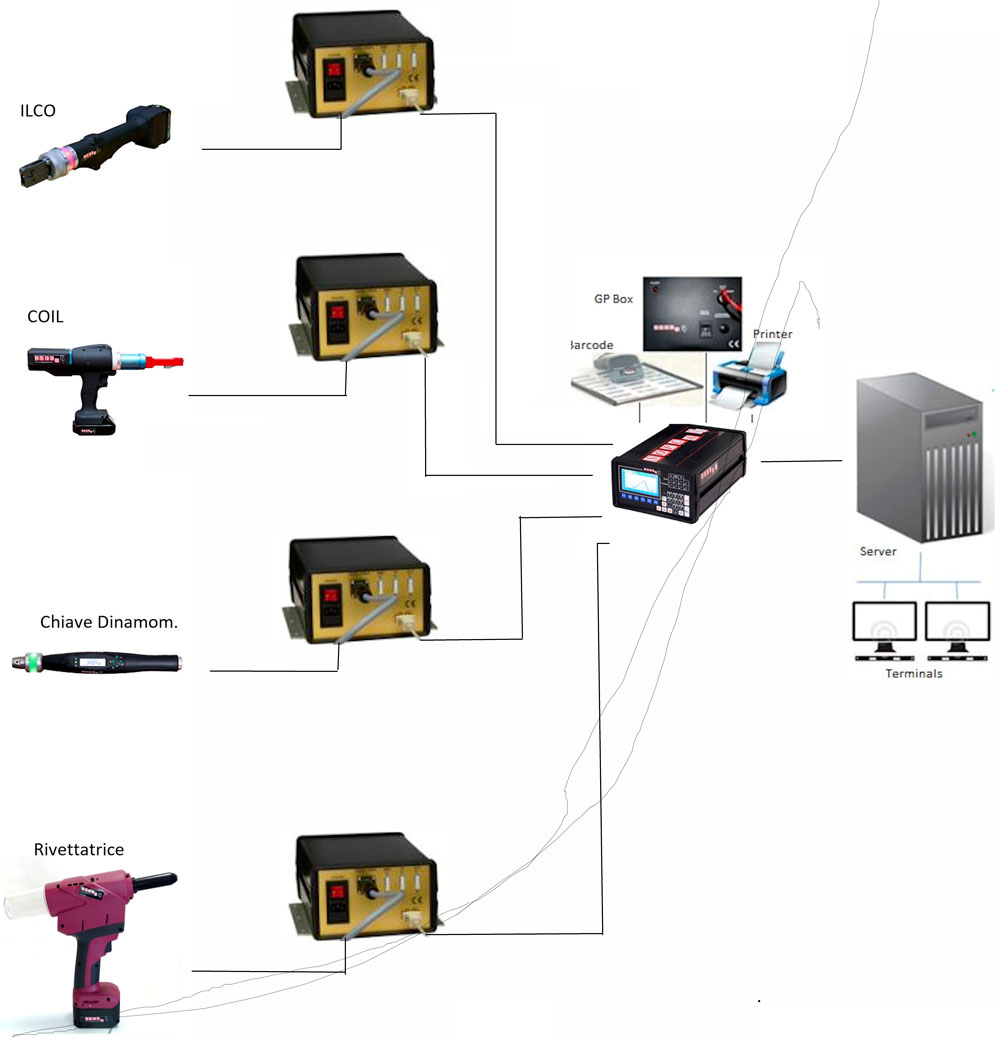

Integrated wired systems with simultaneous operation mode

Each system operates independently of each other; one operator is used for all tools in the group.

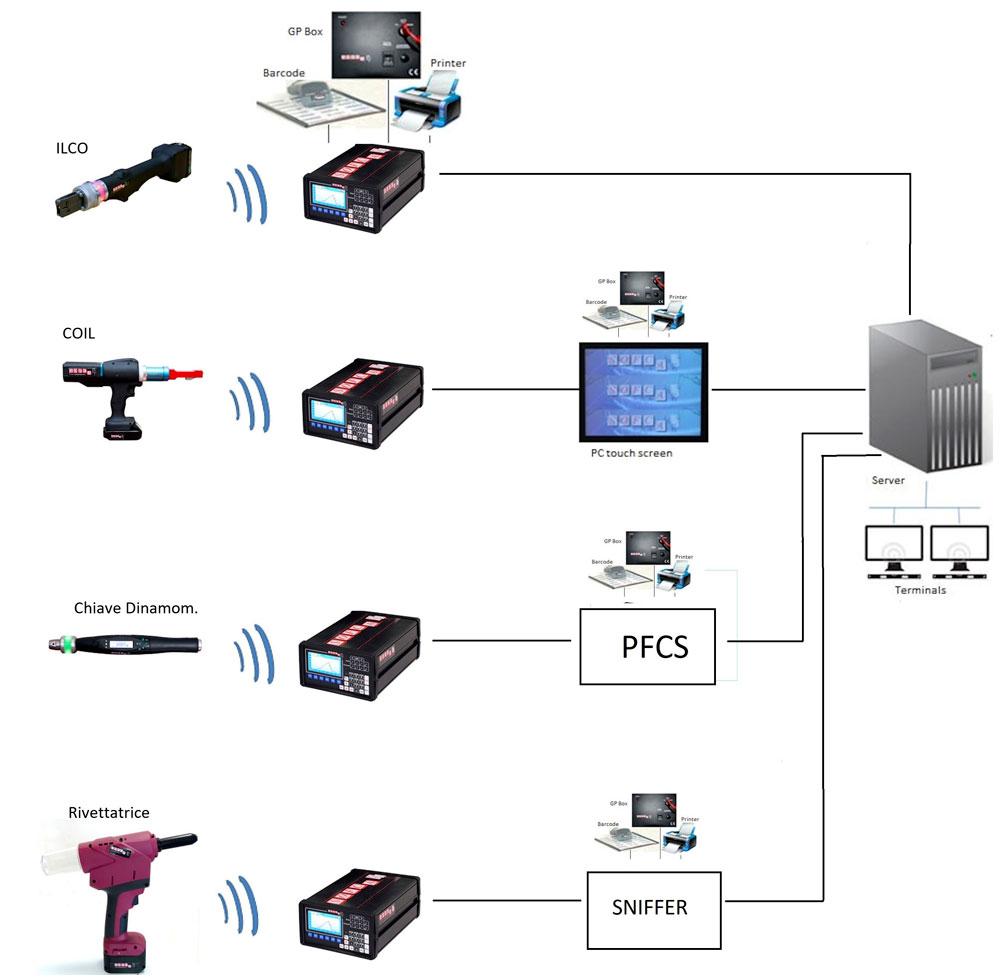

Integrated wireless systems with simultaneous operation mode

If the customer is interested in a wireless solution, groups consisting of two-channel wireless control units SPM-2CH can be used.

We recommend that customers interested in configuring their own integrated system contact the Sofca Sales Office to discuss the optimal technical solution for the project; upon request, Sofca is available to set up the integrated system on special benches.