The SPM Suite program is suitable for COIL, ILCO, Torque Wrench and Riveter systems.

The SPM100 MAK5 control unit can work in slave mode with a Sofca standard industrial touch-screen PC by means of the SPM SUITE program installed on the PC.

The SPM Suite program is suitable for COIL, ILCO, Torque Wrench and Riveter systems.

The SPM100 MAK5 control unit can work in slave mode with a Sofca standard industrial touch-screen PC by means of the SPM SUITE program installed on the PC.

The "SPM SUITE" program is an optional software for Windows that allows remote control of the Control Unit.

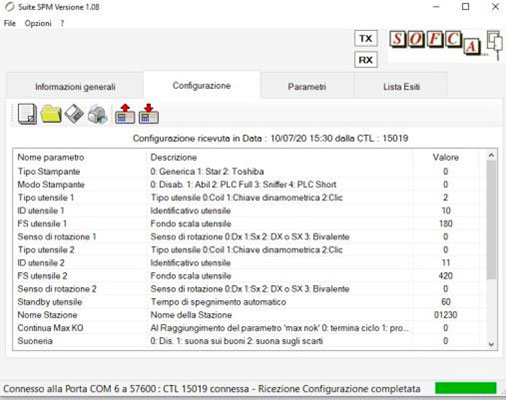

The program is able to recognize and connect to each Control Unit, which is identified by its serial number.

The program, loaded on a Windows PC, is conveniently usable in many fields such as production, maintenance and quality control.

The EVT COIL SUITE allows the following functionalities, on line and off line:

- Remote control of the CCU to set and execute tightening programs; It is possible to start a tightening from PC only for applications designed specifically for automated operations.

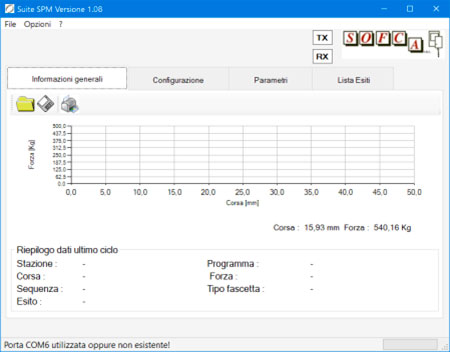

- Display the tightening graphic of the last cycle in high resolution and report the results

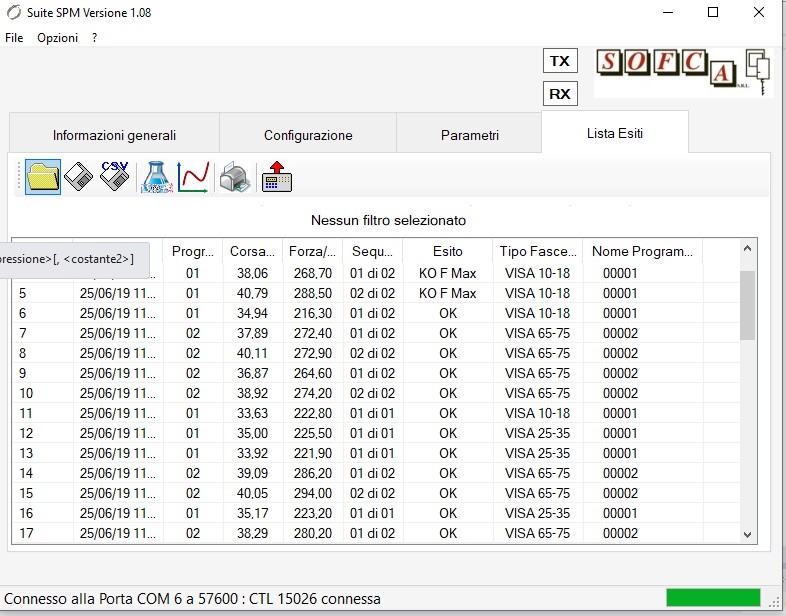

- Store hundreds of thousands of cycle results

- Export data in CSV or customized file to evaluate the production trends; data can be filtered by program, date/hour, tightening parameter, tightening result, clamp type

- Copy and paste tightening parameters from one program to another inside the same Control Unit or among Control Units

- Build, store and retrieve program backups

- Transfer programs from PC to Control Unit and vice versa

You can insert filters into the data view

The results will be saved in text format, CSV and, upon request, on the Data Base.

It is possible to use the SPM SUITE program to see the graph and the result of the clamps performed by the CU, review the list with all the results, download the system configuration and the parameters of the various clamping programs set on the CU. Or, on the other hand, you can use the SPM SUITE program to create a system configuration, set the parameters of various clamping programs, download it all to the CU to make it fit for clamping operations.