The SPM100 riveting system allows the objectification and control of rivet fastening. The system is able to verify the correct force and stroke, count the number of operations that make up the assembly cycle, transfer data to a storing system based on the use of PLC, PC, ETHERNET NETWORK and PC Unit for PFCS/MES protocol.

The SPM100 riveting system allows the objectification and control of rivet fastening. The system is able to verify the correct force and stroke, count the number of operations that make up the assembly cycle, transfer data to a storing system based on the use of PLC, PC, ETHERNET NETWORK and PC Unit for PFCS/MES protocol.

The control unit, both in wireless and “wired” version, is available in the following versions:

- 1 channel

- 2 channels for two operators to work simultaneously

In the two-channel version, the control unit supports any combination of COIL, ILCO, Riveter, Torque Wrench tools:

| CH1 | CH2 | |

| ILCO | + | ILCO |

| ILCO | + | Torque Wrench |

| ILCO | + | COIL |

| ILCO | + | Riveter |

Objectification is a procedure that, when executed, makes a smart equipment capable of monitoring a production process.

The objectification consists of two phases: a programming phase and an execution phase, which includes the series production.

During programming an expert performs a sequence of assemblies that have to be performed properly; in this phase the equipment is set in acquisition mode with the purpose of learning what is being done.

In the next phase of execution the equipment will have to monitor the operations on the production line, verify them with respect to what it has learned previously and, in case, report any anomaly in the values of the measured parameters.

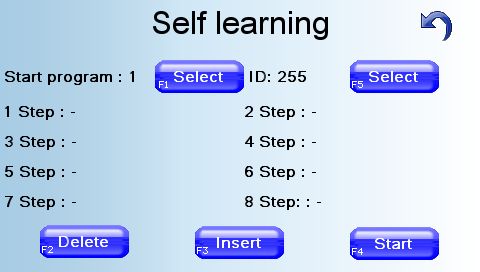

Objectification is implemented through the self-learning function, through which the system is able to determine the range of values relating to the control of the tightening that the technologist can analyze and may correct.

Self-learning screen

The certainty that this force is actually the one due, will be guaranteed by the RIVETING system, which will or will not validate the correct tightenings of the clamp based on the parameters set by self-learning; after which, in production, the system is able to check the correct tightening, count the number of rivets that make up the assembly cycle, transfer the data to a storage system based on the use of a PLC, PC, or ETHERNET NETWORK interacting on an information technology level and in real time with the control systems that contribute to the complex vertical supervision activity according to various types of networks and protocols including PFCS / MES.

For the control and monitoring of the fastening, the control unit is a versatile tool that can work independently or cooperatively with external devices such as the PLC, the program selection device or the Barcode and interface with the systems used by large companies of the automotive field.

The control unit uses the Bluetooth connection to exchange data with the tool.

The use of the Bluetooth system offers the advantage of eliminating the wiring for the transfer of information between the tool and the control system when the tool is used at a distance of no more than 15 meters from the control unit.

The use of a system with Bluetooth technology allows the operator to be autonomous in the handling of the tool during the tightening operations.

Main screen

Statistics screen

The peculiarity of the RIVETING system lies in a better guarantee of the rivet tightness by applying the following strategies:

- Self-learning for setting the parameters that ensure a good tightening of the rivet

- Detection, during the tightening and in real time, of the values of these parameters by reading the sensors and release of data on an external PLC

- Scheduled maintenance to be carried out by the control unit which, based on the implemented cycles, will warn the operator

Characteristics of the RIVETING system:

- Practical system, since there are no cables and hoses to drag

- Tool weight, about 2 kg

- Maintenance limited to the replacement of the consumable

- Long autonomy of the battery, on average it lasts about 8 hours

- Battery replacement in about 4-5 seconds

- About one hour time to charge the 20 VDC lithium battery with the convenience of having the second battery in charge

- Graph of Force/Stroke with indications of their acceptability thresholds after cycle performed

- PLC interface

- Availability of an on-site bench for the verification of the tightening force through the use of a load cell with ACCREDIA reference

Features of the riveting tools

Example of a SPM–SLIM RIVETING configuration

The following figure shows a possible SPM - RIVETING bench, in one of its typical configurations:

- Control Unit SPM– RIVETING

- PC Unit for PFCS/MES protocol

- Dedicated printer for timely report of the operations

- Barcode device to select the appropriate program

- Riveting tool with beacon information

- Customizable bench with anodized aluminum frame

- GP BOX unit for the selection of the riveting program