Various accessories are available; printer, GPBOX, tool/ bushing exchange, barcode, beacon, balancer, tool cradle.

Bushing exchange

With this option it is possible to give an indication to the operator about which bushing to use for the selected program or, vice versa, to run a program according to the bushing taken by the operator. The bushing change has the following features:

- to inform the control unit on which bushing is taken by the operator so that the control unit itself can select the suitable pre-set program and keep track of it in the print report

- vice versa, the control unit communicates to the device in question which bushing must be selected to execute the pre-set program; normally the selected bushing is made visible to the operator through a visual indication

Tool exchange

The Tool Exchange is a device that activates a pre-set program when the operator disengages a torque wrench from its own power supply.

GP Box 5

Tightening operations may be assisted by the GP Box 5 that conveniently allows to:

- select between modes PC, PLC, Manual

- activate the selected program

Printer

Commercial printers or TOSHIBA model printers or STAR model printers can be supplied.

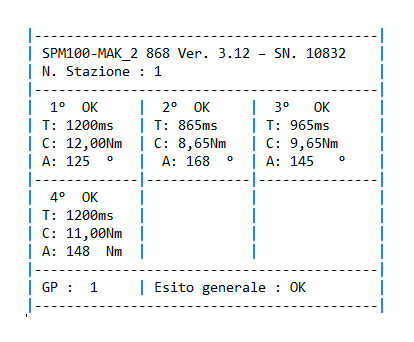

The peculiar printers can print in 'tag' mode as in the example.

Barcode

The barcode reading is an input to the system and allows, for example, to automatically select a tightening program.

Beacon

Used to view the results of an operation according to the color of the light emitted.

Tool cradle

The support can accommodate the tool after each operation.

Balancer

It is a support for the suspension of the tool.

Data Transfer

The data can be transferred to the company server as a file or as an Input to Data Base through ETHERNET connections.