The simulation bench, with anodized aluminum frame, is fully equipped and offers the advantage of being able to run all the tests related to the various tools by providing for each the degree of acceptance and characterization by measuring the CM, CMK and related X/R paper. The bench also allows the recording and the consequent storage of all the data collected which can then be used for statistical purposes.

The simulation bench, with anodized aluminum frame, is fully equipped and offers the advantage of being able to run all the tests related to the various tools by providing for each the degree of acceptance and characterization by measuring the CM, CMK and related X/R paper. The bench also allows the recording and the consequent storage of all the data collected which can then be used for statistical purposes.

The interface to the operator is carried out through a touch screen monitor run by the SPM100 TC ANALYZER control unit, which allows to program and view all the parameters and testing strategies.

The system also provides the necessary data for the statistical analysis of deviations and problems related to them, through a history of all the tests carried out.

The bench and its equipment is dedicated to the testing of torque wrenches with torques up to 500 Nm with an accuracy of 1%.

The Visual Capability software, which allows the management and control of the tests, has a user interface based on a logical and intuitive menu.

The calibration verification of torque wrenches is made by comparison to torque transducer with reference ACCREDIA.

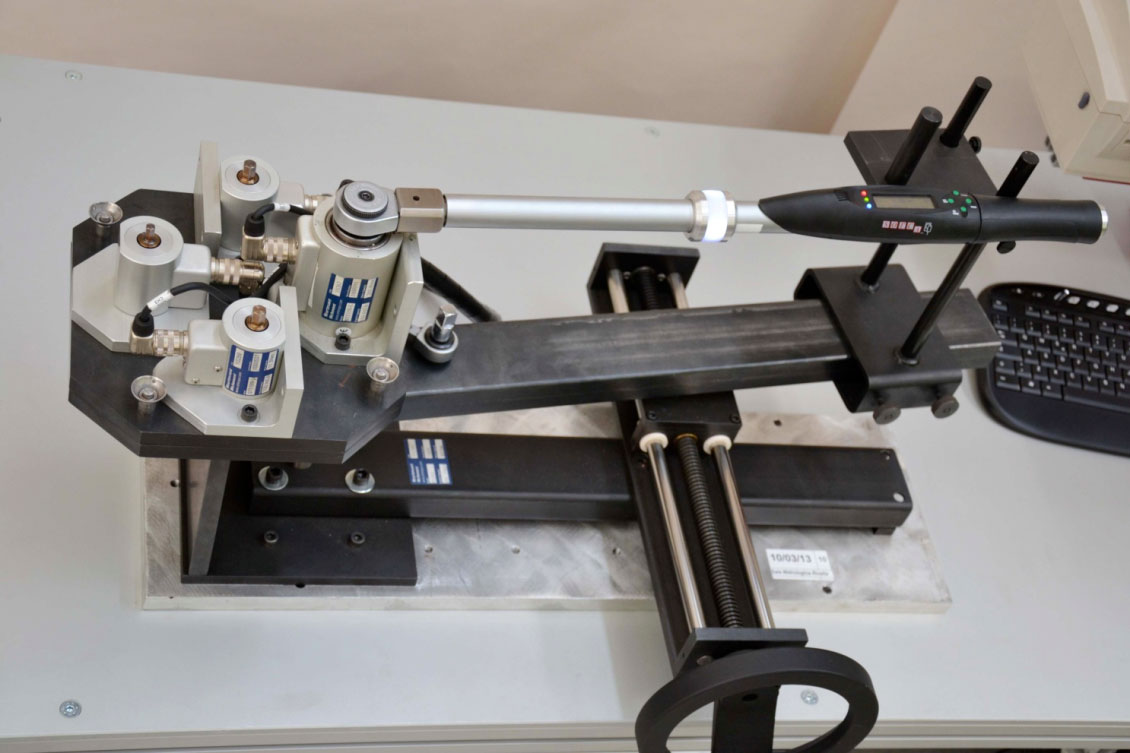

The left side of the bench includes:

- the reaction bars for the appropriate positioning of the wrench under test

- the slide for moving the wrench in order to perform the torque test, clockwise or anti-clockwise

- four reference transducers

- the flange where the four transducers are located, which can be repositioned every 90 degrees so as to have the selected torque in the direction of the reaction bar

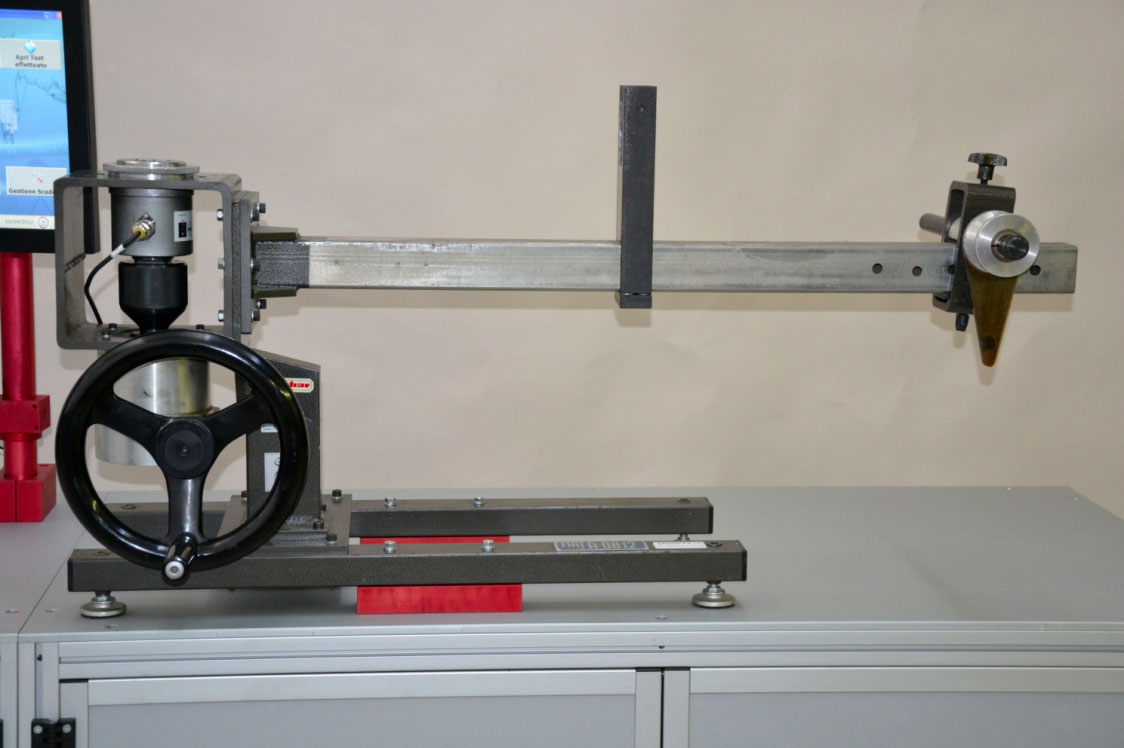

The right side of the bench includes:

- the reaction bars for the appropriate positioning of the wrench under test

- the slide for moving the wrench in order to perform the torque test, clockwise or anti-clockwise

- one reference transducer for high torque values

Inside the bench is the drawer unit, each drawer has its own key.

Inside the bench is the SPM100 TC ANALYZER control unit, which oversees the functioning of the tests in an automatic way.

The central part of the bench includes:

- the industrial PC with the touch-screen monitor, keyboard and mouse

- the Toshiba thermal printer

The Visual Capability software, which is installed on the PC, manages the user interface and the testing

With the Visual Capability software, it is possible to:

- insert the operators enabled to test

- enter the details of the tools under test

- manage the verification deadlines of the tools

- configure the reference transducers

- conduct Test Capability and Linearity Test

- save the test results on the PC and export them in the CSV format or to a Remote Data Base

- print the test results

The bench is also available in the compact version.