Clamping systems

The Bluetooth systems for clamping allow to objectify and monitor the tightening of the VISA®, CLIC, MUBEA/NORMA clamps. The system is able to check the proper tightening, count the number of clamps that make up the assembly cycle, transfer the data to a filing system (PLC, PC, PFCS, ETHERNET network).

All SOFCA clamp tightening systems are patented with European patent number EP3868515.

Gas Treatment Systems

SOFCA has been active for over 25 years in the installation, maintenance and testing of methane and LPG systems. This activity, combined with experience in the development of electronic systems, allows the design and construction of specific calibration benches in the field of gas systems.

Tightening Systems

They include various tools and systems for tightening, from wireless electronic torque wrenches torque & angle for an objectified control to brushless tools with torque, torque & angle detachment and current absorption.

Accessory Equipment

Various accessories are available; printer, GPBOX, tool/ bushing exchange, barcode, beacon, balancer, tool cradle.

Bushing exchange

With this option it is possible to give an indication to the operator about which bushing to use for the selected program or, vice versa, to run a program according to the bushing taken by the operator. The bushing change has the following features:

- to inform the control unit on which bushing is taken by the operator so that the control unit itself can select the suitable pre-set program and keep track of it in the print report

- vice versa, the control unit communicates to the device in question which bushing must be selected to execute the pre-set program; normally the selected bushing is made visible to the operator through a visual indication

Tool exchange

The Tool Exchange is a device that activates a pre-set program when the operator disengages a torque wrench from its own power supply.

GP Box 5

Tightening operations may be assisted by the GP Box 5 that conveniently allows to:

- select between modes PC, PLC, Manual

- activate the selected program

Printer

Commercial printers or TOSHIBA model printers or STAR model printers can be supplied.

The peculiar printers can print in 'tag' mode as in the example.

Barcode

The barcode reading is an input to the system and allows, for example, to automatically select a tightening program.

Beacon

Used to view the results of an operation according to the color of the light emitted.

Tool cradle

The support can accommodate the tool after each operation.

Balancer

It is a support for the suspension of the tool.

Data Transfer

The data can be transferred to the company server as a file or as an Input to Data Base through ETHERNET connections.

Riveting Systems

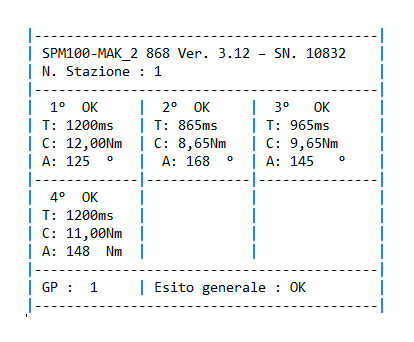

SOFCA srl has designed SPM - RIVETING electronic systems to control the tightenings of the various types of rivets, one controlled by the SPM -100 Wireless control unit and a cheaper one, controlled by the SPM SLIM control unit. Both systems allow the objectification of rivet tightening.

Integrated Systems

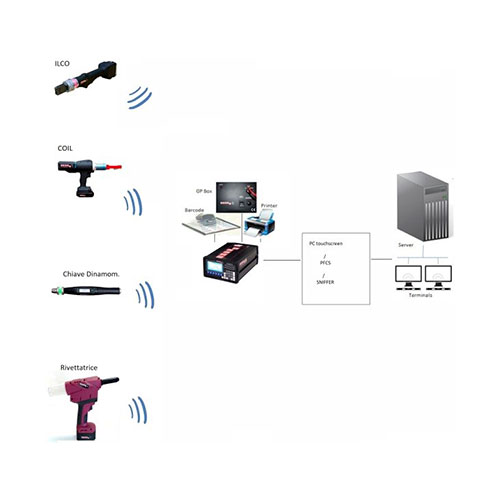

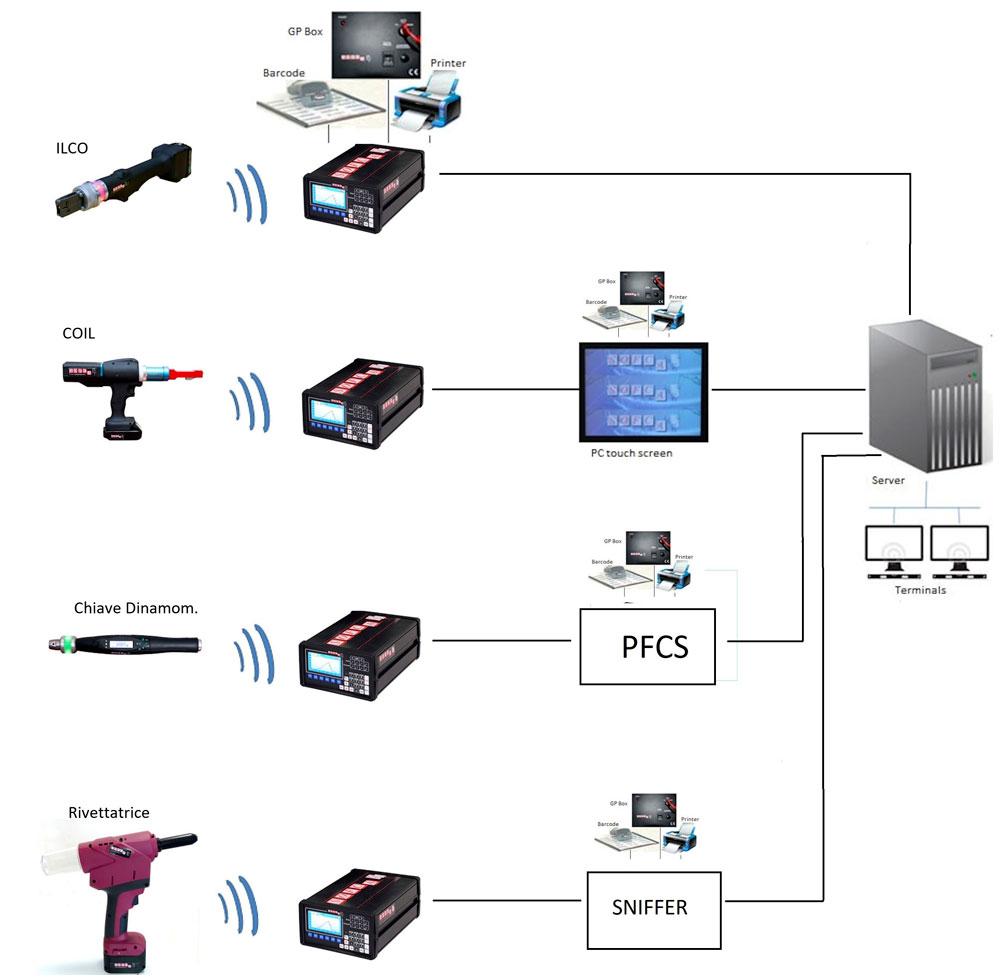

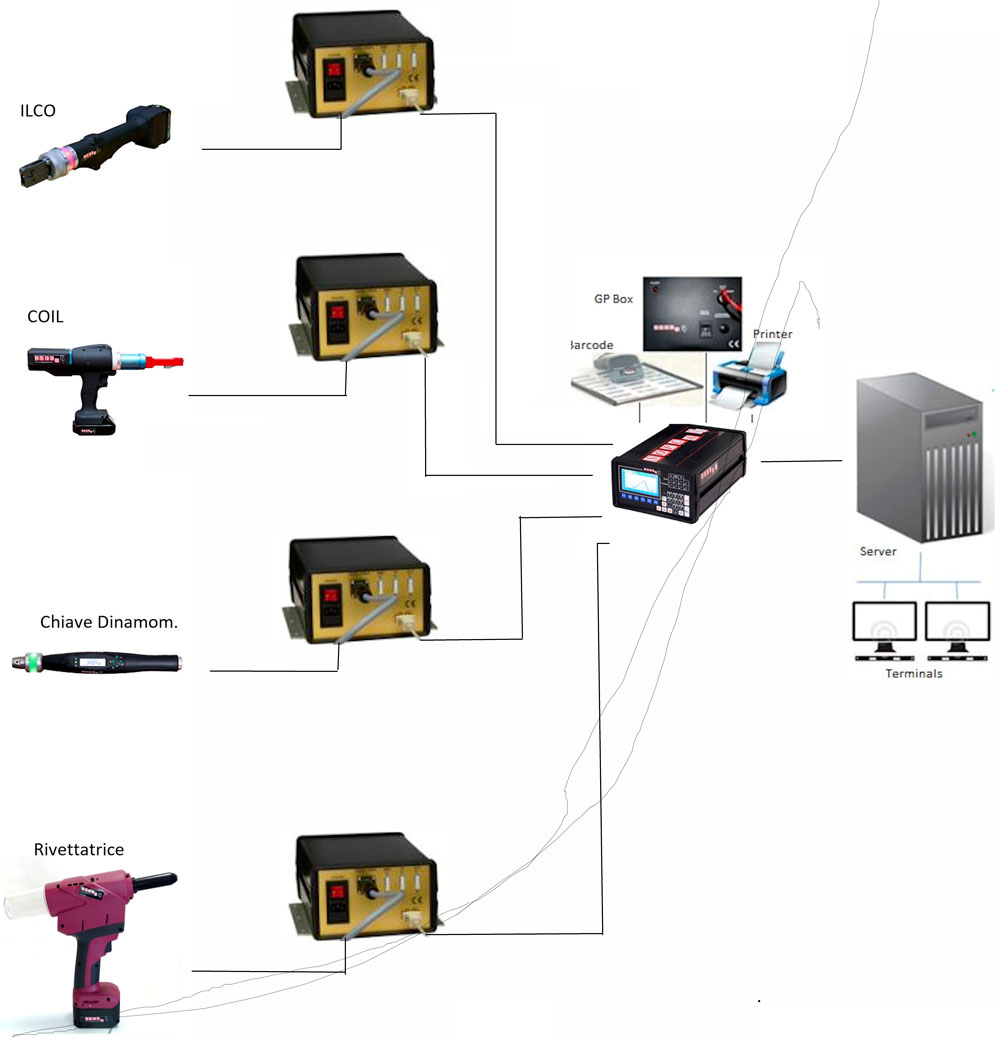

Sofca srl is able to integrate various screwing and tightening tools, used by a plurality of operators, and perform the data transfer to a filing system based on the use of:

- PLC

- PC

- Sniffer

- PFCS

- Company Server

via multiple alternative interfaces, such as:

- Discrete signals

- RS232 / 422 Serial

- Ethernet

- Profinet

interacting on an information technology level and in real time with the control systems that contribute to the complex vertical supervision activity according to various types of networks and protocols including PFCS / MES.

Therefore, systems of various complexity can be configured with centralized data management on the server of the customer's plant, passing from the creation of minimal systems consisting of a tool with control unit, beacon, printer, optional barcode reader to hybrid systems with more than one tool connected to a control unit up to systems integrated with company data management, where the fulcrum of the system is a Sofca standard industrial touch-screen PC.

Three typical configurations can be identified:

- Integrated systems with independent operating mode

- Integrated systems with deferred operating modes

- Integrated systems with simultaneous operation mode

But it is also possible to compose integrated systems with mixed operating modes; they are hybrid systems composed of subsystems of the previous types.

Example:

Integrated systems with independent operating mode

In this case, each system operates independently; one operator per system is employed.

Integrated systems with deferred operating modes

In this case, each system operates virtually independently, but the access by the control unit is divided over time and the control unit is dedicated to one tool at a time after each access; only one operator is used for all the tools in the group.

Example:

Example:

Integrated wired systems with simultaneous operation mode

Each system operates independently of each other; one operator is used for all tools in the group.

Integrated wireless systems with simultaneous operation mode

If the customer is interested in a wireless solution, groups consisting of two-channel wireless control units SPM-2CH can be used.

We recommend that customers interested in configuring their own integrated system contact the Sofca Sales Office to discuss the optimal technical solution for the project; upon request, Sofca is available to set up the integrated system on special benches.

Calibration Benches

The use of a fully equipped simulation bench offers the advantage of being able to carry out all the tests relating to the various tools, providing for each the degree of acceptance and characterization through the measurement of the CM, CMK and related X / R papers, with considerable savings in time and allowing the recording, and consequent filing, of all the data collected which can therefore be used for statistical purposes.

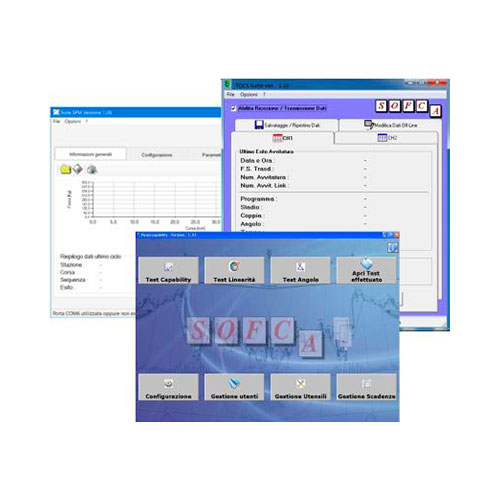

Application Software

Various "user friendly" application programs have been developed to support the main product categories to facilitate remote control, management and interfacing of the various SOFCA systems.

Marking Systems

The marking systems allow to mark the processes and controls carried out in the assembly and testing of production processes such as screwing, welding, thread test, tightness test, denting in a practical and safe way.

Special Equipment

The versatility of Sofca design in many industrial sectors has led to the development of "turnkey" equipment and systems ranging from the creation of sensors to laboratory benches, from the building of mobile vehicles for special surveys to the monitoring of electromagnetic pollution.