The microprocessor controls for brushless tightening tools interface with the electric nutrunners BL with detachment by torque, torque & angle and current absorption.

The microprocessor controls for brushless tightening tools interface with the electric nutrunners BL with detachment by torque, torque & angle and current absorption.

The tools cover torque ranges from 0 to 800 Nm and are mostly used in class A tightenings. Their reliability reaches a degree of accuracy of about 2% of their full scale.

Nutrunners selection

The nutrunners are selectable on the basis of:

- T/A transducer, which ensures a torque and angle control

- I/A transducer, which ensures a current and angle control

- manual nutrunners with insert usually at 90 degrees

- machine nutrunners with straight insert; they are intended for use in array, they are assembled into structures and are controlled automatically

The SPM100 C&A tightening system is available in two versions with the same characteristics, rack version or bench version, and consists of:

- a SPM-TAC control unit with one or two tightening channels

- one drive

- one or two nutrunners

The following configurations are possible in the case of a system with a nutrunner:

| Control Unit | Drive | Nutrunner |

|---|---|---|

| SPM-TAC | BL-L | BL40/5 |

| SPM-TAC | BL-L | BL40/20 |

| SPM-TAC | BL-H2 | BL57/50 |

| SPM-TAC | BL-H2 | BL57/140 |

| SPM-TAC | BL-H4 | BL80/350 |

| SPM-TAC | BL-H4 | BL80-500 |

Example of setting up the tightening system

The following figure shows the configuration of a bench tightening system, consisting of:

- TAC control unit

- Drive for nutrunner

- Dedicated printer with timely report of operations

- Barcode device for selecting control parameters (future extension)

- Nutrunner

- GP BOX unit, consisting of a selector for selecting the tightening program

- TAC SUITE with touch screen PC

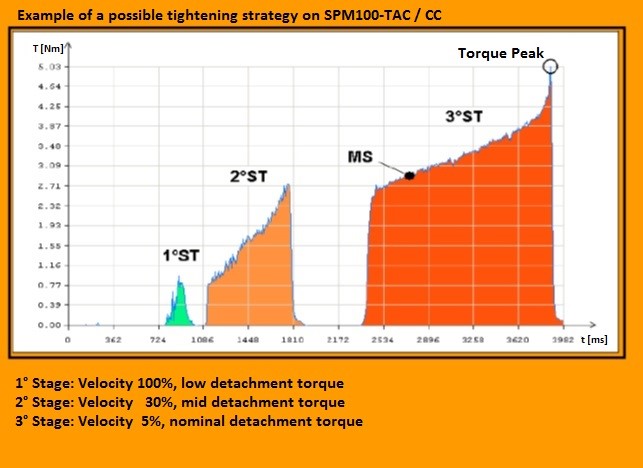

Example of tightening programming

TAC SUITE

The "TAC SUITE" program, owned by SOFCA s.r.l., allows to communicate remotely with the

control unit (CTL), download the information contained in the CTL, modify the CTL configuration

and set the programs, parameters and tightening sequences. The program is able to recognize and

connect to each CTL, which is identified by its serial number.

The program runs on a touch-screen Windows PC and is conveniently usable in many fields such as

production, maintenance and quality control.